ICFs – Build Block System

BUILDBLOCK IS THE MOST

INSTALLER-FRIENDLY ICF ON THE MARKET.

SAVE YOURSELF TIME, MONEY, AND HASSLE FROM BEGINNING TO END. BUILDBLOCK IS DESIGNED TO CREATE THE STRONGEST STRUCTURE, CREATE LESS WASTE, AND INSTALL FASTER THAN OTHER BLOCKS ON THE MARKET.

- Fully reversible blocks with universal interlock.

- Completely assembled and ready to stack.

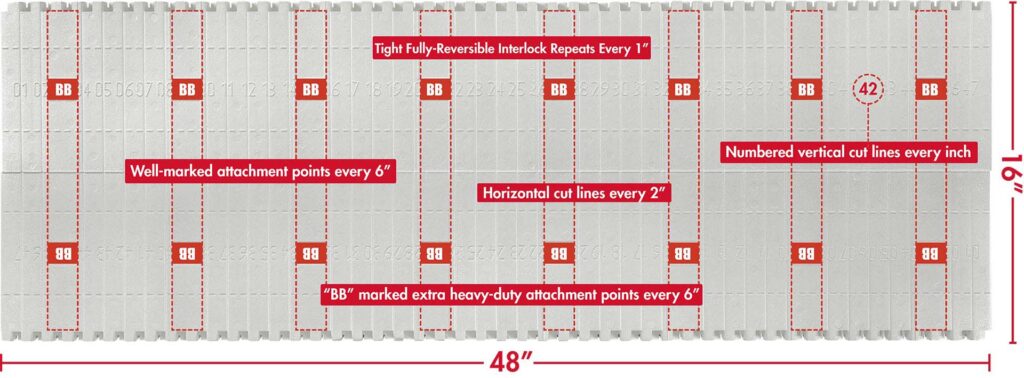

- Industry standard size: 16 inches high x 48 inches long

- Strongest interlocking connections for greater stability, precision alignment and eliminates extra costs in zip ties or special clips.

- Self-draining interlock to help prevent water or ice from building up during construction.

- Built-in 1-inch repeating cut pattern dramatically reduces waste.

- Molded horizontal cut lines and integrated numbered vertical cut lines make cuts easy and eliminate the need for a tape measure before every cut.

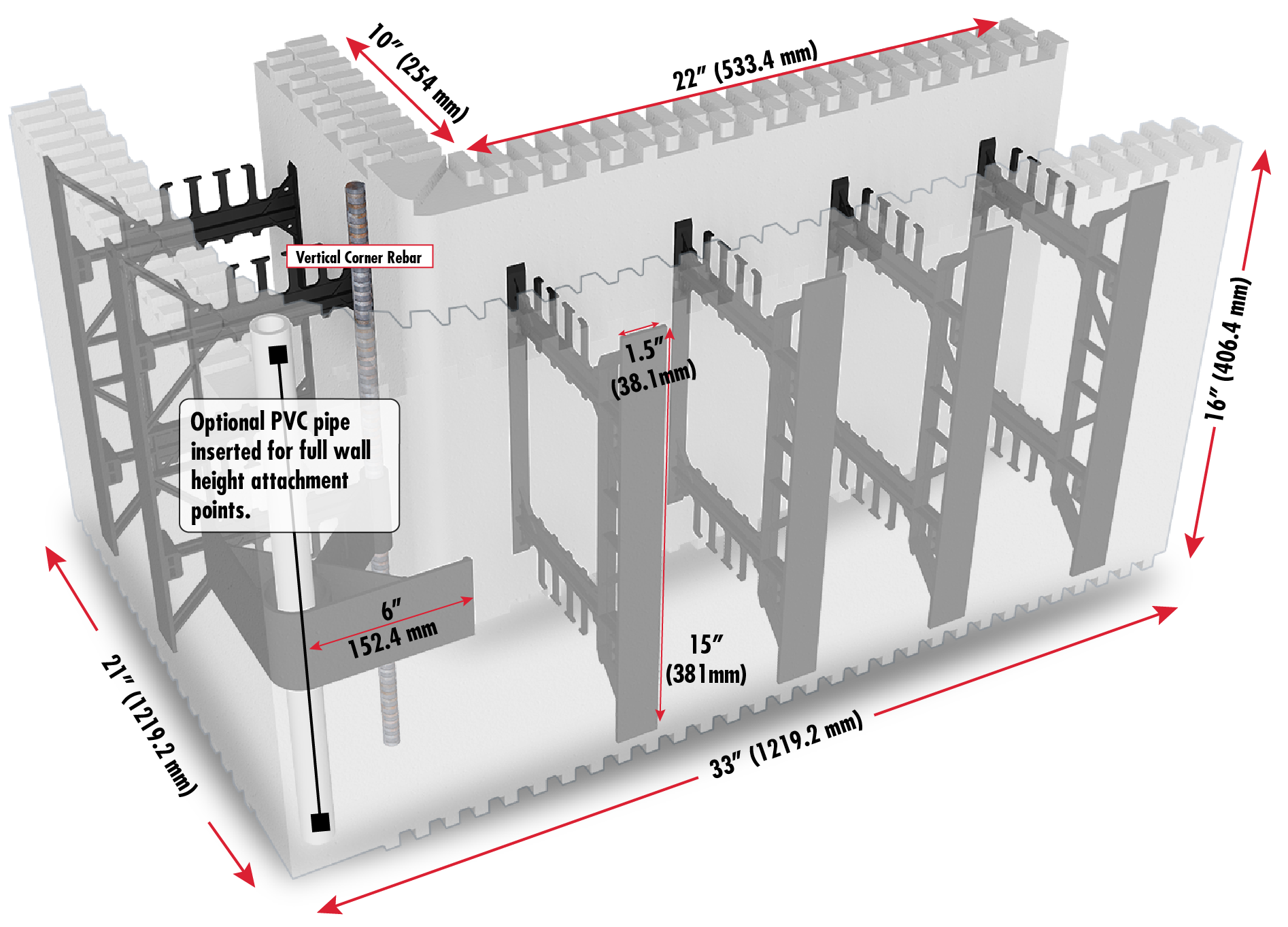

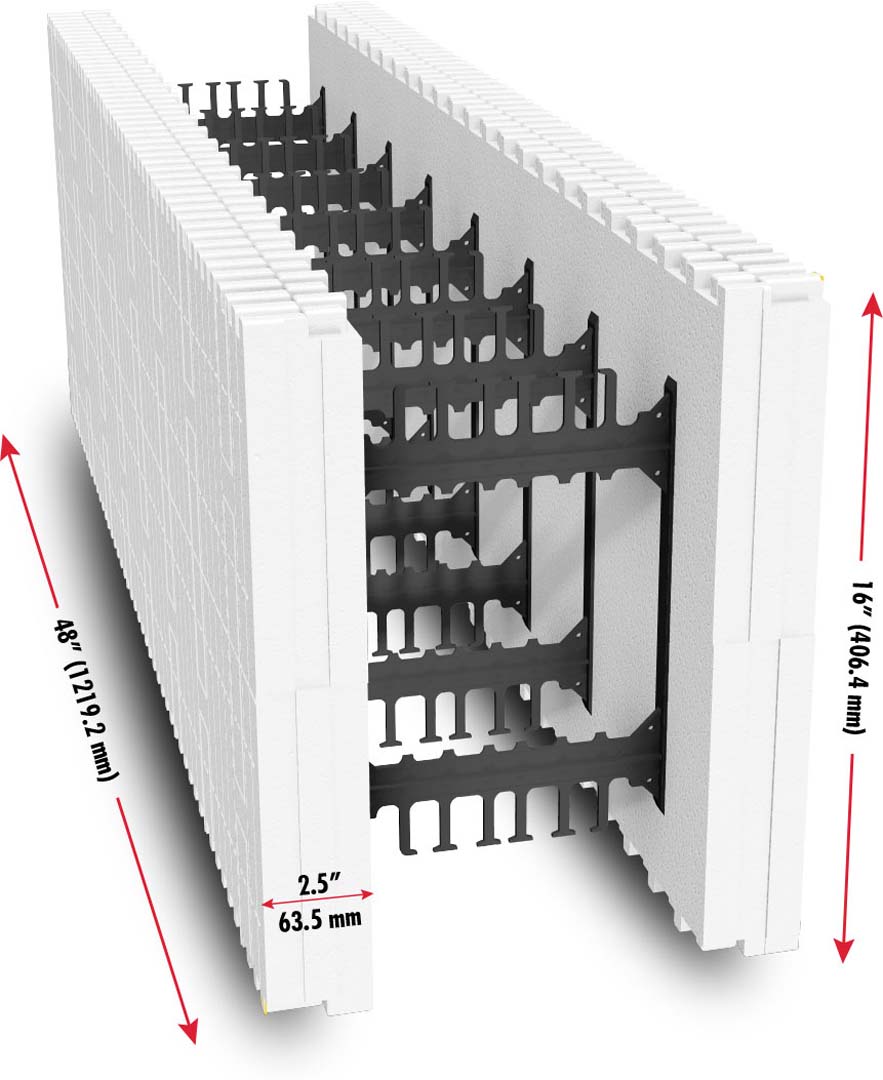

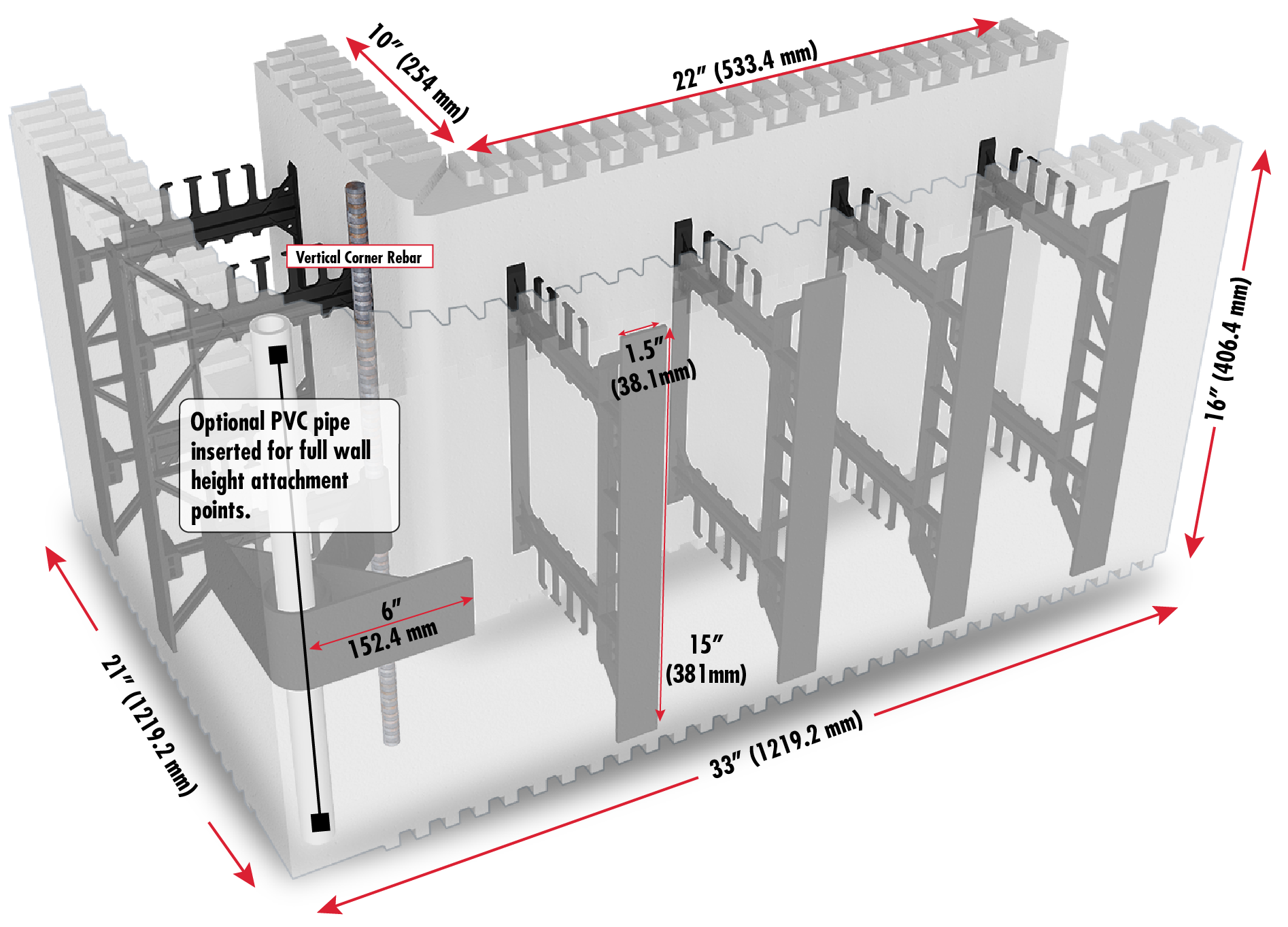

- High-density plastic webs are molded into place every 6 inches on center creating integrated insulated studs every 6-inches.

- The full height webs have the same strength as wood and are insulated 1/2-inch behind the foam to prevent thermal transfer.

- The patented BB hard points are spaced every 8-inches vertically. These 450lb+ attachments are designed to hold heavy cabinets, stairs and other finishes.

- Patented and award-winning technology.

Fully Reversible Form

BuildBlock ICFs are 100% reversible while the vast majority of all ICFs are non-reversible or only partly reversible. This means when you pick up a BuildBlock© ICF, you don’t waste your time determining if the ICF needs to be turned up or down or left or right to be installed. With a reversible ICF like BuildBlock©, it always fits no matter which way you turn it. When it comes to corners, one BuildBlock ICF corner is the same for right or left applications. Non-reversible ICFs come in left and right-hand corners which create several disadvantages. First, our distributors tell us they can’t count the times when they’ ve picked up the wrong corner with other ICFs and marched to the far end of an installation only to find they needed the other hand corner. Second, when you get to the last course there is a good chance you will have the wrong corners (left or right) remaining. The waste factor for fully reversible ICFs can be as little as 1 or 2%, while waste factors of 5% or more are common with non-reversible ICFs. When using products other than BuildBlock ICFs, you must take this into account, as well as the extra cost for the extra ICFs needed to do the job.Longer Corner Blocks

BuildBlock 90° and 45° ICF corner blocks are 6″ longer on each leg than the industry standard. The many advantages this gives to our product include shorter offsets that get you past the crucial short offset. This eliminates many hours of extra corner bracing and extra strapping. The longer corner blocks prevent corner pullout and head joints from opening up leaving you with a wall that isn’t plumb or straight. When corners pull out this can typically lead to blowouts which are common in the industry among other ICFs. The extended corner form significantly reduces corner shifting and enhances the overall stability of every pour. On a 4 to 5 day job, this can amount to a full days savings in labor costs.Tie Web Spacing/Attach Points

BuildBlock ICFs have web spacing on 6-inch centers. Most ICFs come with 8 to 12-inch spacing on the webs. This is a cost-cutting feature and as a result, reduces the overall performance and quality of the project. The 6-inch spacing eliminates the scallop effect of the concrete pressure distorting the ICFs on the outside during the pour. Also, it further reduces the chance of any blowouts. Having two extra furring strips per block per side (which are part of each web) give sheet rockers more attachment points to fasten to. Webs are expensive and having two more webs in our ICFs gives you the most value added product on the market. All furring strips are 15″ tall by 1.5″ wide per 16″ course and have two distinctive marked (sweet) spots on each furring strip at 8-inch centers vertically and 6-inch centers horizontally. These spots have a screw pull out strength that is roughly equivalent to wood or structural steel studs (close to 500lbs). Deeper snap-in rebar saddles accommodate two #5 rebar and the patented corner tie is 6″ x 6″ wide and 2.5″ tall for simplified corner attachments. All ties or furring strips are recessed-inch to allow stucco or EIFS applications as approved by the manufacturers.Numbered and Marked Cut Lines

BuildBlock ICFs have horizontal and vertical cut lines on both sides of the ICF which allow for much faster and more efficient installation times. The ability to pick a horizontal line for your window and door headers saves countless time in the field. No need for a level to mark a level line to cut on. There is no longer a need to measure your vertical cuts. Simply note the measurement number on the block and cut on its line for a custom cut piece that fits every time. Half Height Cutting BuildBlock ICFs are easily cut in half to make half height forms. With the unique web design, the half height form needs no additional bracing. This allows for special height walls without wasting half a block or more on each cut. Use both halves thus eliminating the waste and the extra cuts needed with other ICFs. This also eliminates the need to order special height forms with other systems (if they make them). In addition, the built-in rebar scallops on the inside of the web will also hold your rebar in place as well.Horizontal Connections

BuildBlock ICFs are not a tongue-and-groove or ship-lap-style form. There are a few brands of ICFs on the market that still use the old school technology. They are much inferior to modern ICFs since tongue and groove blocks don’t have interlocking nubs. This causes other ICFs to be more material and labor intensive (including using excessive amounts of glue, strapping tape, zip-ties, form lock, bracing and crew training). BuildBlock©s 1-inch repeating pattern and its molded cut lines pre-align the installation of our ICF and eliminate block alignment issues that other ICFs create. This eliminates block misalignment and the built-in furring strips from not lining up, giving you a better job every time. Just wait until you have to explain to your sheet rockers why the furring strips don’t line up with the use of older style forms. The self-alignment of BuildBlock© ICFs solves all these headaches and many more. This also reduces the need for glue and other methods of holding the blocks together. Waste on every project is further reduced.Block Bonding

BuildBlock ICFs bond out to even and odd inches from outside to outside and inside to outside corners. They also have a minimum bump factor of -inch when necessary. Of all ICFs in the industry today that have interlocking nubs, most of them have a bump factor of 1 inch or more. (Some ICFs have up to a 6-inch bump factor.) This transforms into less waste on every project as well as walls that match the floor plans of your designs. Another great benefit of BuildBlock’s interlocking connections is the self-draining nature of the design. When it rains, water doesn’t pool in the connections as can occur with other ICFs. Therefore, in freezing weather, there’s no water to freeze keeping you from stacking the next day until everything thaws.Fully Reversible Form

When it comes to corners, one BuildBlock ICF corner is the same for right or left applications. Non-reversible ICFs come in left and right-hand corners which create several disadvantages. First, our distributors tell us they can’t count the times when they’ ve picked up the wrong corner with other ICFs and marched to the far end of an installation only to find they needed the other hand corner. Second, when you get to the last course there is a good chance you will have the wrong corners (left or right) remaining. The waste factor for fully reversible ICFs can be as little as 1 or 2%, while waste factors of 5% or more are common with non-reversible ICFs. When using products other than BuildBlock ICFs, you must take this into account, as well as the extra cost for the extra ICFs needed to do the job

Long & Stronger Corners

This makes sure that corners reach further into the walls to tightly lock the corner in place, help prevent lifting and spreading during the pour. Braced appropriately this extra reach greatly reduces hours of extra corner bracing and extra strapping material. The longer corner blocks prevent corner pullout and head joints from opening up leaving you with a wall that isn’t plumb or straight.

When corners pull out this can typically lead to blowouts which are more common in the industry among other ICFs. The extended corner form significantly reduces corner shifting and enhances the overall stability of every pour. On a typical job, this can amount to a full day’s savings in labor costs.

Tighter Web Spacing

Stronger Webs & Attachments

This is a cost-cutting feature and as a result, can reduce the overall performance and quality of the project. The 6-inch spacing eliminates the scallop effect of the concrete pressure distorting the ICFs on the outside during the pour.

It also further reduces the chance of any blowouts. Two additional webs in the block provides significantly more strength and having two extra furring strips per block per side (which are part of each web) give sheet rockers more attachment points to fasten to. Webs are expensive and having two more webs in our ICFs gives you the most value added product on the market. All furring strips are 15″ tall by 1.5″ wide per 16″ course and have two distinctive marked (sweet) spots on each furring strip at 8-inch centers vertically and 6-inch centers horizontally. These spots have a screw pull out strength that is roughly equivalent to wood or structural steel studs (close to 500lbs). Deeper snap-in rebar saddles accommodate two #5 rebar and the patented corner tie is 6″ x 6″ wide and 2.5″ tall for simplified corner attachments. All ties or furring strips are recessed-inch to allow stucco or EIFS applications as approved by the manufacturers.

Molded Tape Measure & Cut Lines

Easy Half-Height Block Cutting

Strong 1" Repeating Interlock

BuildBlock ICFs feature 1″ repeating connectors to provide a tight interlock that’s fully reversible.